Encaustic Cement Tile Explained

Encaustic Cement Tile Explained

There's a lot of confusion as well as a lot of mystery surrounding the distinction between encaustic tiles, encaustic cement tiles, and concrete tiles. Although it might seem like a trivial issue or even a practice in semantics, it is crucial to be aware of the differences between the two kinds of tiles and the places you should and shouldn't make use of these types of tiles. This process begins by knowing the different ways tiles are made and concludes by ensuring you are satisfied with the purchase, by identifying the perfect style and looking to complete the task.

Encaustic and Cement Tiles Vary in How They are Made

It's not difficult to understand why the names cement tile and encaustic get confused. The distinction between these kinds of tiles is in the method by which they're created. Additionally, this confusion can be exacerbated since nearly everyone uses the terms interchangeably including tile manufacturers and tile suppliers. Both encaustic and cement tiles are not glazed. In addition, the tiles appear quite similar when placed. We'll now discover the difference between cement and encaustic tile.

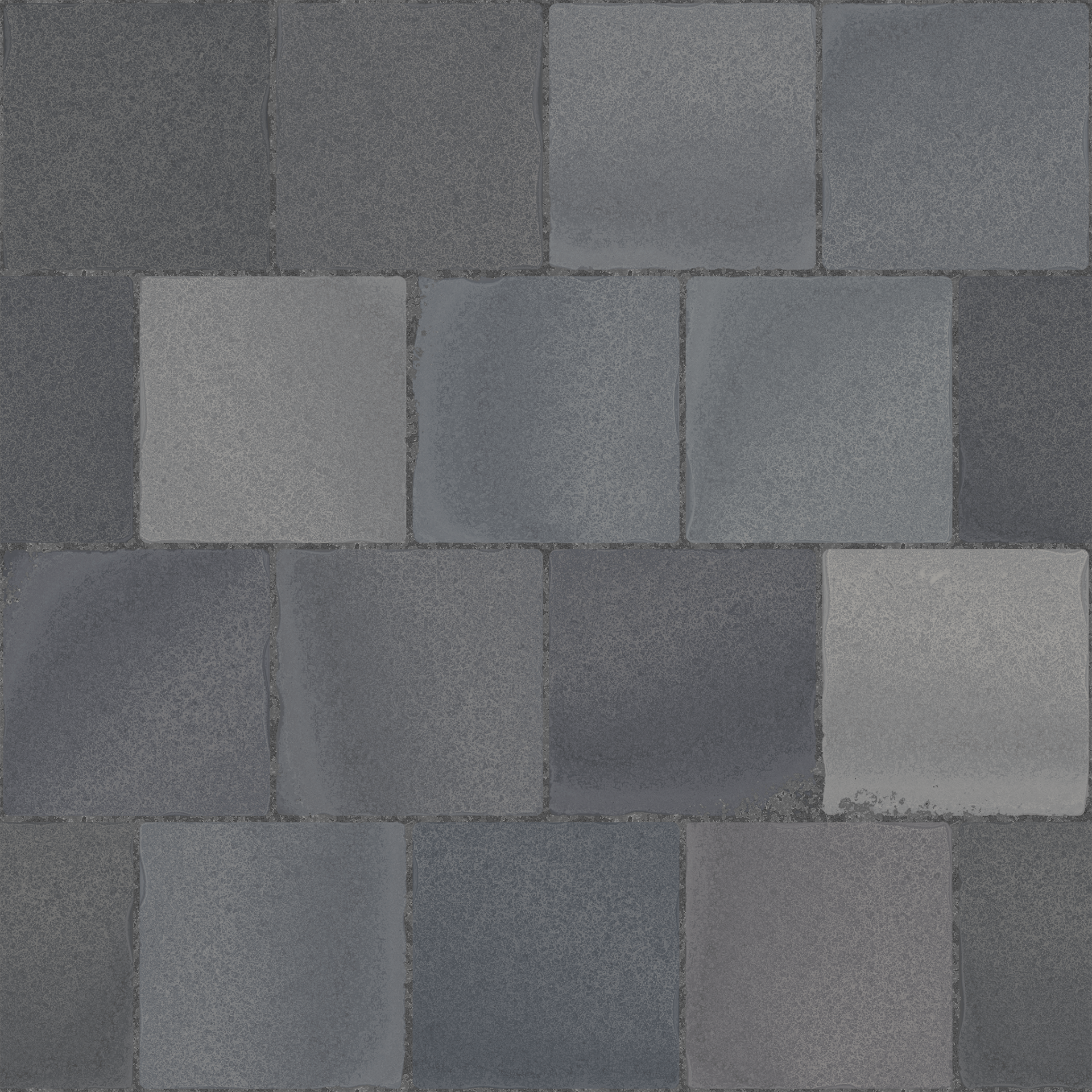

Encaustic tile can be considered resistant to frost and is suitable for use in all outdoor settings. The cement tile that is hydraulically pressed cannot be used in areas that are susceptible to hard freezes. It is usually found within Mediterranean and Tropical climates. Now you can understand the significance of knowing the different types of tiles and how they are utilized. But some pre-cast concrete tiles are frost-proof and suitable for outdoor applications in cold climates.

How Encaustic Tile Is Made?

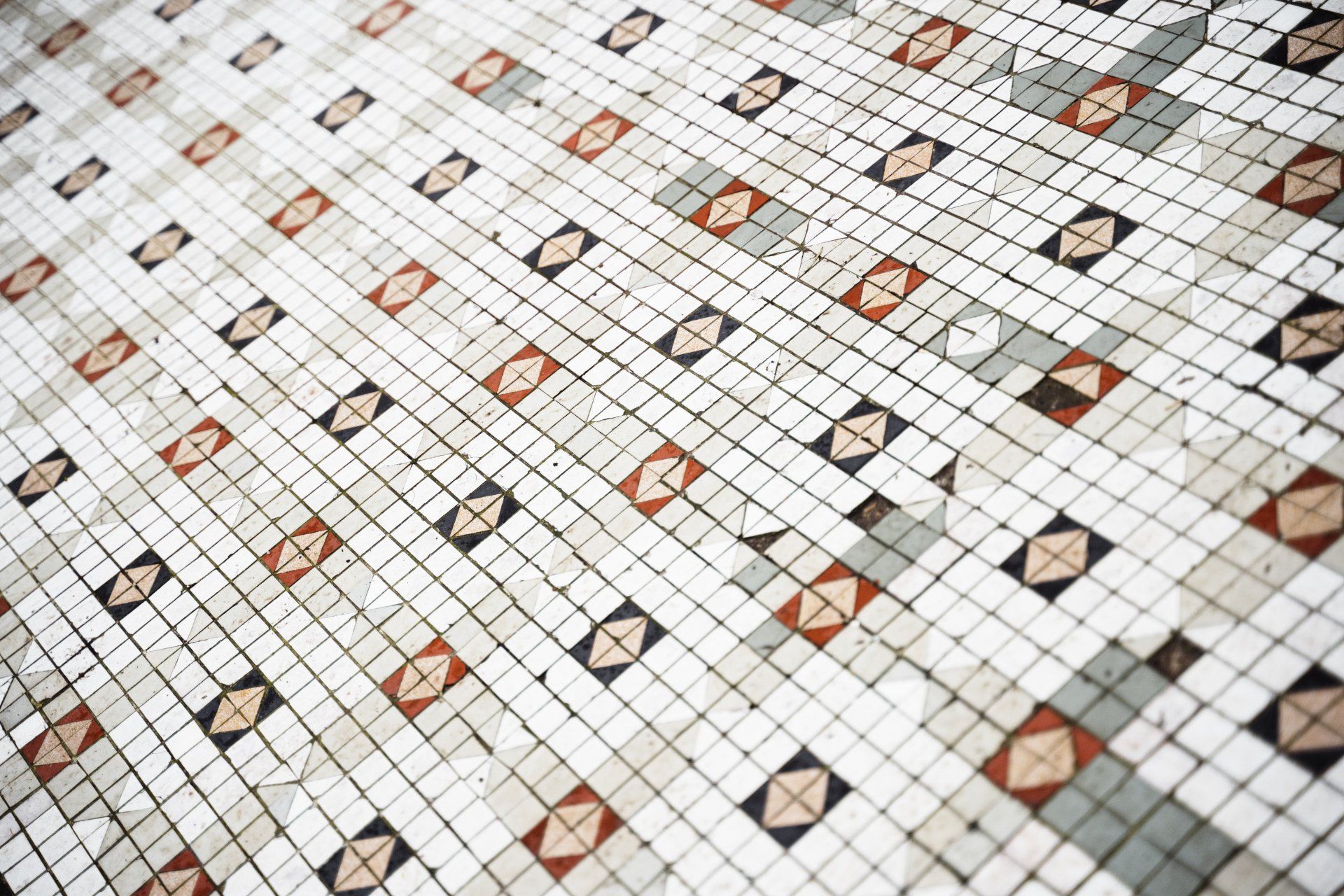

Encaustic tiles are constructed of two or more shades of clay that are bonded together to form the pattern. The tiles are fired afterward. Tiles made of encaustic have been in use since the time of the medieval era. However, the use of encaustic tiles as an artistic form reached its peak around the mid-1800s when the well-known manufacturer, Minton's Ltd, became the main supplier of durable decorative surfaces for flooring and walls in public buildings, churches, and grand palaces. The U.S. Capitol sports a Minton tile floor made of encaustic. Even today, England has the most popular encaustic tile installations since Minton tile belongs to an English firm.

How Encaustic Cement Tile Is Made?

Encaustic cement tiles consist of concrete. The color of the pattern is derived from mineral pigments that are mixed and then poured into molds. This technique was first developed around the turn of the century and hasn't been altered much since the time it was developed. The pattern isn't painted or glazed as is the case with most ceramic tiles that are decorative; however, it is embedded into the inside of the tile with the mold.

The term "encaustic" was originally used to refer to the method of enameling; however, in the 19th century, it was used to refer to tile work that was inlaid because of its similarity to enamel work. This could explain why encaustic tile, which is created using clay inlaid and then fired to create patterns or patterns, as well as an encaustic tile which is constructed using colored concrete inlaid with molds, are often both referred to as encaustic tiles.

Encaustic cement tiles, or cement tiles, are created by hand, using an elaborate process. Three different layers compose the encaustic cement tiles. The initial layer forms the top layer, also known as the patterned portion of the tile. The grid is patterned at the bottom of the square mold. A color mix of white cement and marble powder along with natural colors are put into each area that is a grid.